White corundum

Composed of crystalline aluminium oxide, this very pure material has high hardness and a regular shape.

It is used where ferrous contamination must be avoided, it is in fact a non-ferrous and non-aggressive abrasive, mainly used in special applications (aviation sector and reactor construction) such as the cleaning of stainless steels, aircraft components and turbines, non-ferrous metals and their alloys, plastic and glass.

The natural characteristic of corundum is its exceptional ability to quickly abrade all types of material; it is suitable for sandblasting with recycling due to its high impact resistance.

It is non-toxic, free of substances harmful to health, does not cause silicosis and is not hygroscopic. The high degree of purity and the absence of contaminating impurities make it possible to obtain surfaces that are perfectly clean and ready for further processing.

Red brown corundum

It is composed of crystalline aluminium oxide and is characterised by its toughness and ability to quickly abrade all types of material. It is suitable for sandblasting with recycling thanks to its high impact resistance.

It has a wide range of applications:

- removal of rust, oxides and burrs from iron and steel constructions

- deburring and finishing of castings

- roughening of surfaces, pre-painting, Teflon coating, lamination and rubber coating

Garnet

It is a mineral belonging to the garnet group that is used for metal processing and treatment in various sectors.

Its high hardness, low friability and high specific weight make it suitable for sandblasting operations, with which an excellent degree of cleanliness can be achieved.

Thanks to the absence of free silica it enjoys chemical inertia, is easily disposable and guarantees a safe working situation as it does not give rise to harmful dust.

The use of garnet ensures higher blasting speeds and lower abrasive consumption, as it can be reused several times without any loss of effectiveness.

Moreover, given its ease of disposal and the possibility of reuse, it is an economical material.

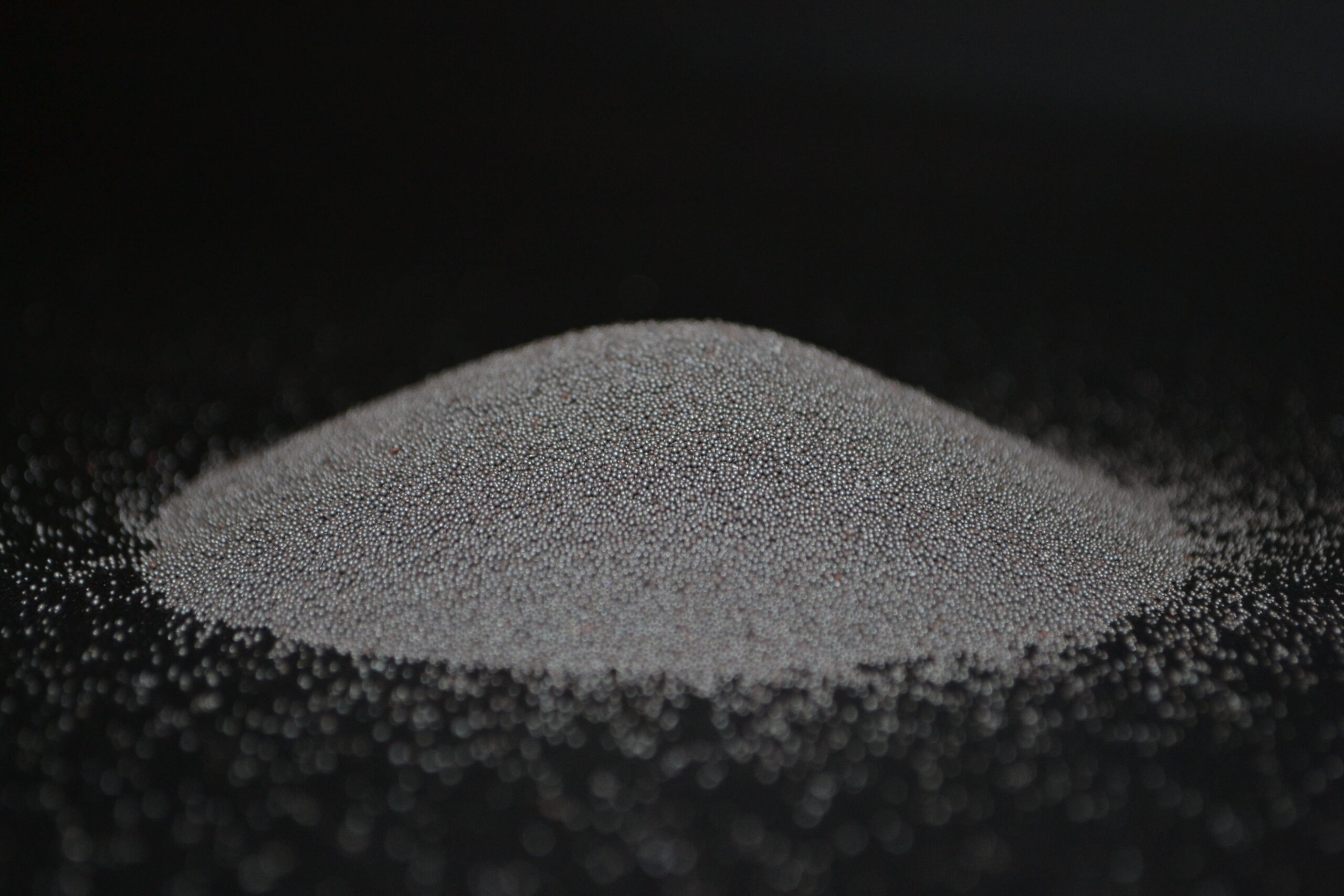

Spherical or angular metal grit

It is used for shot blasting, sandblasting, shot peening and in all cases where it is necessary to prevent the presence of ferrous residues from causing rust stains.

Metal grit is suitable for all kinds of treatment on all kinds of surfaces. It is produced in smelting plants from selected, high quality raw materials; appropriate thermal processing gives the grit a remarkable toughness that results in a high blasting speed and a good abrasive life.

Recommendations for use:

- spherical metal grit for descaling, simple deburring, shot peening and sand removal operations

- angular metal grit (G, GP, GL, GH) for descaling, deburring and surface preparation before coating

Ceramic microspheres

Produced in an ultra-high temperature casting process. The exceptional mechanical properties (impact resistance, hardness and elasticity) allow the microspheres to retain their initial shape and to wear out slowly, without cracking or increasing in hardness.

Ceramic is the most valuable abrasive for air blasting, both in terms of quality of finish, lustre and product life, as well as minimal wear on nozzles, turbines and valves.

The impact resistance of ceramic microspheres reduces consumption and operating costs; the abrasive generates little dust and ensures good visibility.

Their high density makes it possible to reduce the blasting pressure while still achieving the same cleaning effect. In the case of very stubborn dirt, the pressure can be increased up to 6 bar.

Glass microspheres

They are highly resistant to wear and impact. They are used for the surface cleaning of workpieces where any alteration of the material to be treated must be avoided. They allow satin-finished surfaces with minimal roughness.

They are chemically inert, do not contain lead, sulphides and silica in their free state; they do not pollute the areas to be processed.

Corn cob

Is produced from the ear of maize by extracting the fibrous and dried part; it is then ground to the desired grain size.

It is mainly used in the mechanical industry to degrease, clean and dry metal and small parts, as it prevents the formation of surface stains.

Areas of use:

- construction for restoring wood surfaces, marble, terracotta, etc.

- chemical industry as a carrier for pharmaceuticals, phytopharmaceuticals and hand-washing paste

- mechanical industry for cleaning, drying and polishing technical parts or manufactured articles (bolts, washers, spheres, buttons, coins, taps)

- jewellery and silverware for mechanical polishing of jewellery and technical parts